- CHINESE

- 13925554735

A car that enjoys people needs to be precise. Drive your horsepower, drive on the high speed, give your ears better hospitality, and make your life more tasteful. The car horn bracket has irreplaceable credit. In the role of quality control in the automotive industry, the company developed an economical, time-saving and convenient inspection solution for the car horn bracket, which overcomes several major defects such as low detection efficiency, unqualified inspection quality, and high cost of inspection. The contact type coordinate measuring instrument provided can detect the full size of the bracket more efficiently, quickly and economically, and has unique detection technology in extending the service life of the bracket.

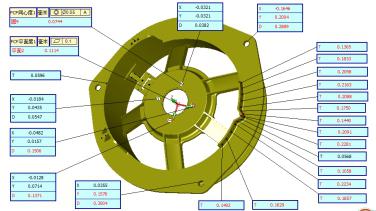

Car horn bracket detection mainly includes: point, line, surface, roundness, relative position, distance, curvature and so on. The three-coordinate measuring instrument is mainly made of granite material in hardware, and many patented technologies are used to ensure the accuracy detection. And the configured PC-DMIS software can easily evaluate the above elements, once programming, multiple use, really saves time and trouble.

The specific testing scheme is as follows:

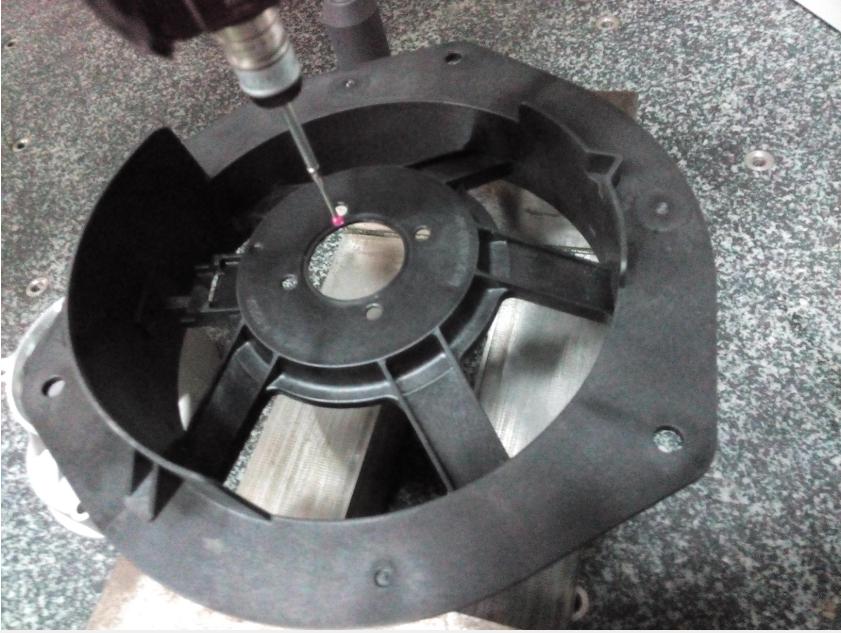

Step 1: Use a flexible combination fixture for product fixing

Step 2: Import the product 3D model for comparative measurement

Step 3: Click on the digital model to calculate the position to generate the measurement program.

Step 4: Generate test report