Usage:

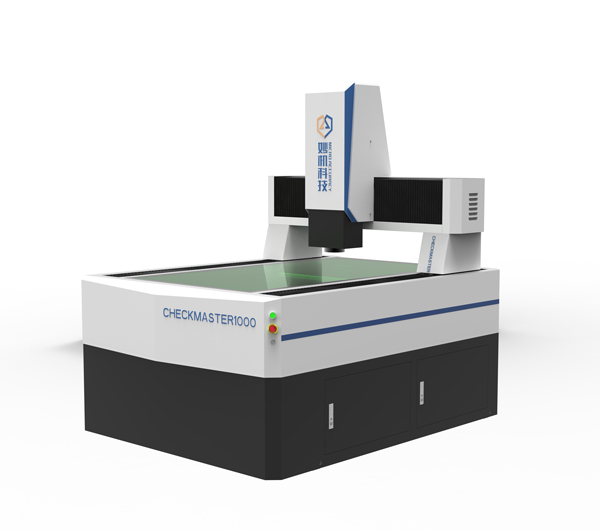

Checkmaster series automatically middle travel Multi sensor measuring system is suitable for all application fields for 2D coordinate measurement. 3D as well. It is widely used in LCD, LED display, touch screen, mobile phone tablet, large glass products, auto parts, large PCB, film, television, hardware, molds, instruments, plastics, precision electronics, precision machinery and so on.

Features:

■ High-precision marble base and column to ensure high stability and rigidity

■ THK/HIWIN high precision linear guide and TBI grinding grade ball screw

■ Panasonic full-closed-loop servo motor, speed can be adjusted

■ RSF high precision non-contact grating scale with resolution 0.0005mm

■ Programmable 5-ring 8-zone annular surface light to meet different angle lighting requirements

■ Fully automatic zoom lens, no need re-calibrate when changing magnification, save calibration time and avoid human error

■ Optional Renishaw contact probe for height, depth and other 3D measurement

■ Optional THK linear guide and ball screw

■ Optional KEYENCE laser displacement sensor for roughness, flatness surface measurement

■ Optional spectral confocal sensor for measuring small and sensitive surfaces