Auto parts have the characteristics of high quality, large batch size and different shapes. According to different component features and measurement types, it is mainly divided into three types: box, complex shape and curved surface. According to materials and processing technology, parts can be divided into thin-walled parts, machine-added parts, pipe parts, and soft parts. Parts and electronic components. Different solutions can be selected according to different detection requirements of different types of parts of different types of parts.

GLOBALSilver Series Bridge Measuring Machine - Universal Measurement Solution

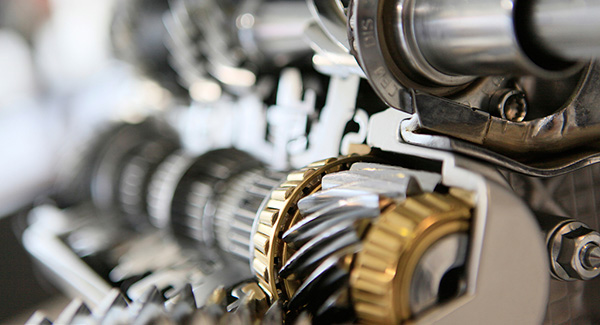

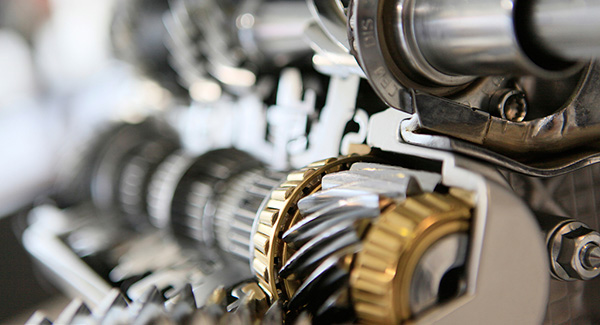

The machine-added parts of the automotive industry are characterized by high quality requirements, large batch sizes, and various shapes. As a general-purpose precision measuring device, GLOBALSilver is able to solve the detection tasks of almost all types of geometric features, and has become the main measuring device for the current automotive industry including powertrains. The device can be equipped with point-trigger, analog trigger scanning and optical scanning probes, and equipped with powerful PC-DMIS measurement software with an accuracy of 1.4+3L/1000[μm], which guarantees the manufacture of high-quality auto parts.

ROMER Absolute Articulating Arm Measuring Machine - Flexible Portable Measurement Solution

With the goal of improving user productivity and portability, ROMER portable absolute arm can perform 3D point cloud measurement and mapping, point trigger detection and other tasks online. It is not only suitable for common rule geometrical inspection, but also an ideal solution for efficient inspection and mapping of complex curved surface parts such as sheet metal parts, stamping parts and pipe parts. It can also be flexibly used for interior parts, body parts and chassis parts. Detection.

Optiv composite image measuring system - high-quality quality inspection of small and thin soft parts

Optiv's hybrid multi-sensor measurement technology combines optical and trigger measurements in a single system that selects the most appropriate sensor for inspection based on the 3D geometry, material, reflective properties and accuracy requirements of the workpiece. The system supports optical sensors, trigger sensors, TTL lasers and innovative white light sensors (CWS). Equipped with powerful PC-DMISVision measurement software, it provides offline programming, CAD comparison, multi-feature and simultaneous capture. Optiv is a powerful assistant for the miniaturization of parts in the automotive industry.